Brakes - what do they do?

The simple answer : they slow you down.

The complex answer : brakes are designed to slow down your vehicle but probably

not by the means that you think. The common misconception is that brakes squeeze

against a drum or disc, and the pressure of the squeezing action is what slows

you down. This in fact is only part of the reason you slow down. Brakes are

essentially a mechanism to change energy types. When you're travelling at speed,

your vehicle has kinetic energy. When you apply the brakes, the pads or

shoes that press against the brake drum or rotor convert that energy into

thermal energy. The cooling of the brakes dissipates the heat and the

vehicle slows down. This is all to do with The First Law of Thermodynamics,

sometimes known as the law of conservation of energy. This states that energy

cannot be created nor destroyed, it can only be converted from one form to

another. In the case of brakes, it is converted from kinetic energy to thermal

energy.

Thermodynamics, brake fade and drilled rotors.

If you ride a

motorbike or drive a race car, you're probably familiar with the term brake

fade which is used to describe what happens to brakes when they get too hot.

A good example is coming down a mountain pass using your brakes rather than your

engine to slow you down. By the First Law of Thermodynamics, as you start to

come down the pass, the brakes on your vehicle heat up, slowing you down. But if

you keep using the brakes, the drums or discs and brake pads will stay hot and

get no chance to cool off. The next time you try to brake, because the brake

components are already so hot, they cannot absorb much more heat. Once they get

to this stage, you have to look at the brake pads themselves. In every brake pad

there is the friction material which is held together with some sort of resin.

Once this lot starts to get too hot, the resin holding the pad material together

starts to vapourise, forming a gas. That gas has to have somewhere to go,

because it can't stay between the pad and the rotor, so if forms a thin layer

between the two trying to escape. The result is very similar to hydroplaning

while going too fast in the rain; the pads lose contact with the rotor, thus

reducing the amount of friction. Voila. Brake fade.

If you ride a

motorbike or drive a race car, you're probably familiar with the term brake

fade which is used to describe what happens to brakes when they get too hot.

A good example is coming down a mountain pass using your brakes rather than your

engine to slow you down. By the First Law of Thermodynamics, as you start to

come down the pass, the brakes on your vehicle heat up, slowing you down. But if

you keep using the brakes, the drums or discs and brake pads will stay hot and

get no chance to cool off. The next time you try to brake, because the brake

components are already so hot, they cannot absorb much more heat. Once they get

to this stage, you have to look at the brake pads themselves. In every brake pad

there is the friction material which is held together with some sort of resin.

Once this lot starts to get too hot, the resin holding the pad material together

starts to vapourise, forming a gas. That gas has to have somewhere to go,

because it can't stay between the pad and the rotor, so if forms a thin layer

between the two trying to escape. The result is very similar to hydroplaning

while going too fast in the rain; the pads lose contact with the rotor, thus

reducing the amount of friction. Voila. Brake fade.

The typical symptom of this would be to get the vehicle to a stop and wait for a

few minutes. As the brake components cool down, their ability to absorb heat

returns, the pads cool off which means they have more chance to heat up again

before the resin vapourises, hence the next time you use the brakes, they seem

to work just fine.

So how do the engineers design brakes to reduce or eliminate brake fade? You

give that vapourised gas somewhere to go. Cross-drilled or grooved brake rotors.

While grooving the surface may reduce the specific heat of the rotor, its effect

is negligable in the grand scheme of things. The rotors will heat up to cool

down no faster or slower. However, under heavy braking once everything is hot

and the resin is vapourising, the grooves give the gas somewhere to go, so the

pad can continue to contact the rotor, allowing you to stop.

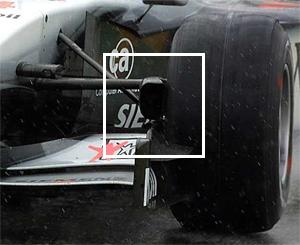

The whole understanding of the conversion of energy is critical in understanding

how and why brakes do what they do, and why they are designed like they are. If

you've ever watched Formula-1 racing, you'll see the front wheels have huge

scoops inside the wheel pointing to the front (see the picture on the right).

This is to duct air to the brake rotors to help them cool off because in

Formula-1 racing, the brakes are used viciously every few seconds and spend a

lot of their time trying to stay hot. Without some form of cooling assistance,

the brakes would be fine for the first few corners but then would fade and

become near useless by half way around the track.

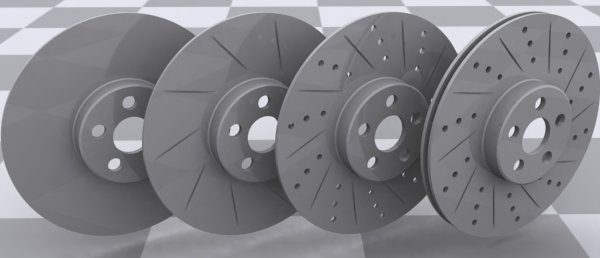

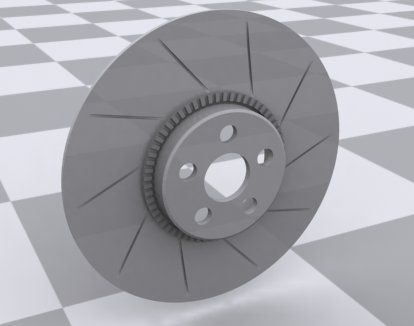

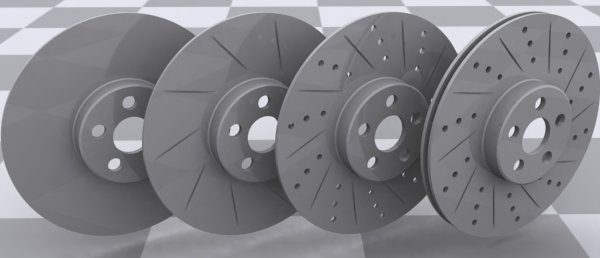

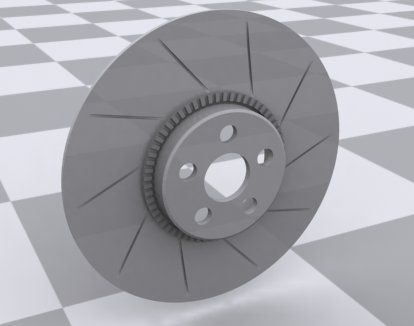

Rotor technology.

If a brake rotor was a single cast chunk of steel, it would have terrible heat

dissipation properties and leave nowhere for the vapourised gas to go. Because

of this, brake rotors are typically modified with all manner of extra design

features to help them cool down as quickly as possible as well as dissapate any

gas from between the pads and rotors. The following diagram shows some examples

of rotor types with the various modification that can be done to them to help

them create more friction, disperse more heat more quickly, and ventilate gas.

From left to right.

1. Basic brake rotor. 2. Grooved rotor. The grooves give more bite and thus more

friction as they pass between the brake pads They also allow gas to vent from

between the pads and the rotor. 3. Grooved, drilled rotor. The drilled holes

again give more bite, but also allow eddy currents to blow through the brake

disc to assist cooling and ventilating gas. 4. Dual ventilated rotors. Same as

before but now with two rotors instead of one, and with vanes in between them to

generate a vortex which will cool the rotors even further whilst trying to

actually 'suck' any gas away from the pads.

Big rotors.

You know I've been drumming into you the whole mechanism that causes you to

stop? Here's another reason. Sports cars and race bikes typically have much

bigger discs or rotors than your average family saloon car. The reason? Heat and

friction. A bigger rotor has more material in it so it can absorb more heat.

More material also means a larger surface area, which as well as meaning more

area for the pads to generate friction with, also translates to better heat

dissipation. ie. bigger rotors = better stopping power.

Taking it one step further, composite brake rotors, as found on high-end

Ferraris, the McLaren F1, and most Formula-1 race cars, are even better again at

heat transfer.

The different types of brake.

All brakes work by friction. Friction causes heat which is part

of the kinetic energy conversion process. How they create friction is down to

the various designs.

Bicycle wheel brakes

I thought I'd cover these because they're about the most basic

type of functioning brake that you can see, watch working, and understand. The

construction is very simple and out-in-the-open. A pair of rubber blocks are

attached to a pair of calipers which are pivoted on the frame. When you pull the

brake cable, the pads are pressed against the side or inner edge of the bicycle

wheel rim. The rubber creates friction, which creates heat, which is the

transfer of kinetic energy that slows you down. There's only really two types of

bicycle brake - those on which each brake shoe shares the same pivot point, and

those with two pivot points. If you can look at a bicycle brake and not

understand what's going on, the rest of this page is going to cause you a bit of

a headache.

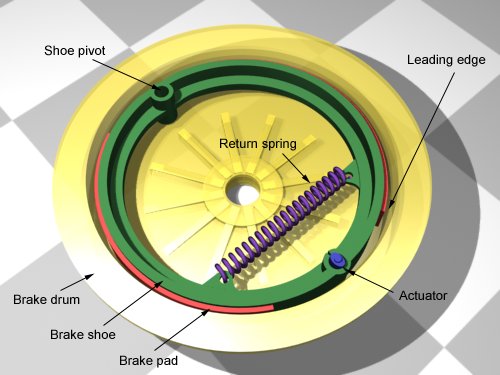

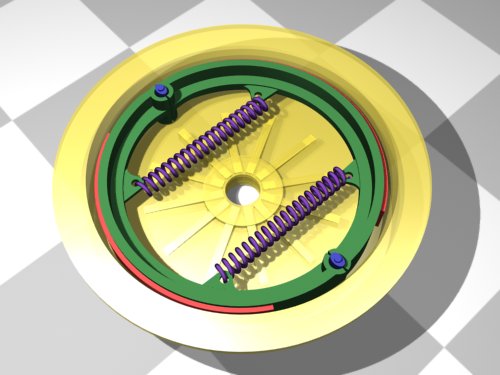

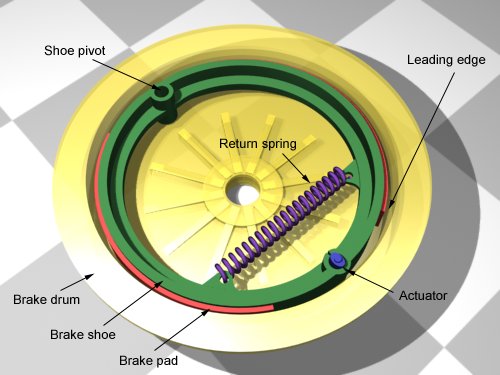

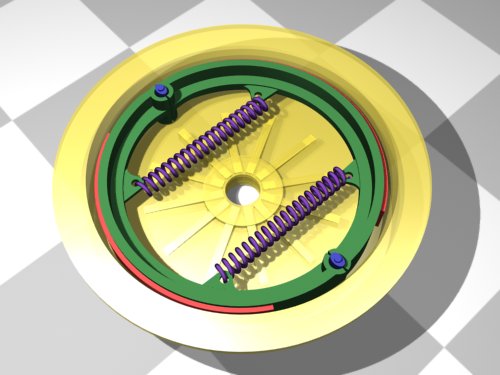

Drum brakes - single leading edge

The next, more complicated type of brake is a drum brake. The

concept here is simple. Two semicircular brake shoes sit inside a spinning drum

which is attached to the wheel. When you apply the brakes, the shoes are

expanded outwards to press against the inside of the drum. This creates

friction, which creates heat, which transfers kinetic energy, which slows you

down. The example below shows a simple model. The actuator in this case is the

blue elliptical object. As that is twisted, it forces against the brake shoes

and in turn forces them to expand outwards. The return spring is what pulls the

shoes back away from the surface of the brake drum when the brakes are released.

See the later section for more information on actuator types.

The "single leading edge" refers to the number of parts of the

brake shoe which actually contact the spinning drum. Because the brake shoe

pivots at one end, simple geometry means that the entire brake pad cannot

contact the brake drum. The leading edge is the term given to the part of the

brake pad which does contact the drum, and in the case of a single

leading edge system, it's the part of the pad closest to the actuator. The

diagram below shows what happens as the brakes are applied. The shoes are

pressed outwards and the part of the brake pad which first contacts the drum is

the leading edge. The action of the drum spinning actually helps to draw the

brake pad outwards because of friction, which causes the brakes to "bite". The

trailing edge of the brake shoe makes virtually no contact with the drum at all.

This simple geometry explains why it's really difficult to stop a vehicle

rolling backwards if it's equipped only with single leading edge drum brakes. As

the drum spins backwards, the leading edge of the shoe becomes the trailing edge

and thus doesn't bite.

Drum brakes - double leading edge

The drawbacks of the single leading edge style of drum brake can

be eliminated by adding a second return spring and turning the pivot point into

a second actuator. Now when the brakes are applied, the shoes are pressed

outwards at two points. So each brake pad now has one leading and one trailing

edge. Because there are two brake shoes, there are two brake pads, which means

there are two leading edges. Hence the name double leading edge.

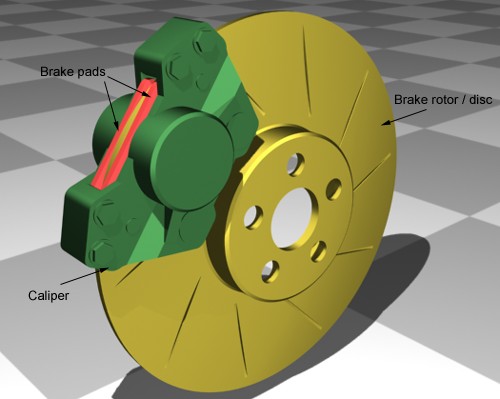

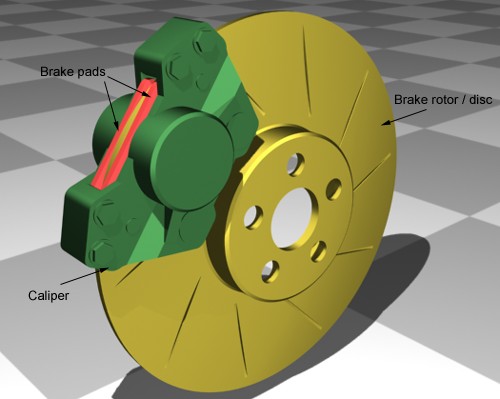

Disc brakes

Disc brakes are an order of magnitude better at stopping

vehicles than drum brakes, which is why you'll find disc brakes on the front of

almost every car and motorbike built today. Sportier vehicles with higher speeds

need better brakes to slow them down, so you'll likely see disc brakes on the

rear of those too.

Disc brakes are again a two-part system. Instead of the drum, you have a disc or

rotor, and instead of the brake shoes, you now have brake caliper assemblies.

The caliper assemblies contain one or more hydraulic pistons which push against

the back of the brake pads, clamping them together around the spinning rotor.

The harder they clamp together, the more friction is generated, which means more

heat, which means more kinetic energy transfer, which slows you down. You get

the idea by now.

Standard disc brakes have one or two cylinders in them - also

know as one or two-pot calipers. Where more force is required, three, or more

cylinders can be used. Sports bikes have 4- or 6-pot calipers arranged in pairs.

The disadvantage of disc brakes is that they are extremely intolerant of faulty

workmanship or bad machining. If you have a regular car disc rotor which is off

by so much as 0.07mm (3/1000 inch) it will be Hell when you step on the brakes.

That ever-so-slight warp or misalignment is going to spin through the clamped

calipers at some ungodly speed and the resulting vibration will make you wonder

if you're driving down stairs. To combat this problem, which is particularly

critical on motorbikes, floating rotors were invented.

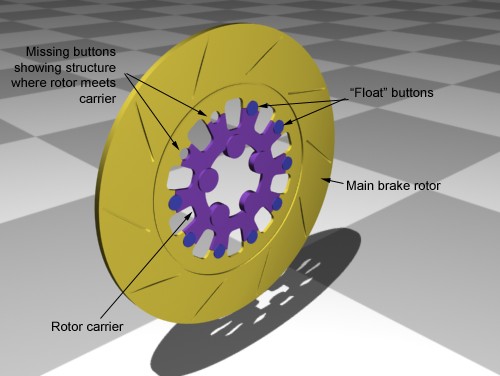

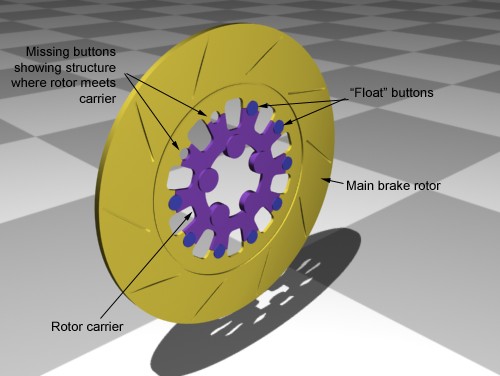

The floating rotor.

Standard brake rotors are cast in a single piece which bolts directly to the

wheel or drive plate. If the mounting surface of your wheel or drive plate isn't

perfectly flat, you'll get vibration at speed. Floating rotors are typically

cast in two pieces - the rotor and the carrier. The carrier is bolted to the

wheel and the rotor is attached to the carrier using float buttons. The other

method of floating a brake rotor is to have the rotor bolted directly to the

wheel itself without a carrier, but the bolts have float buttons built into

them.

These buttons allow the brake rotor some freedom to move

laterally, but restrict the angular and rotational movement as if they were

bolted directly to the wheel. This slight lateral motion which can be less than

0.03mm, is just enough to prevent vibration in the brake system. Because the

calipers are mounted solidly, and warping or misalignment in the wheel or brake

rotor mounting face can be compensated for because the rotor will "float"

laterally on the float buttons. This side-to-side vibration is separated from

the carrier by the float buttons themselves, so none of the resulting motion is

transferred into the suspension or steering. Clever eh? The rendering below

shows an extreme close-up of the brake disc shown above. I've rendered the

components slightly transparent so you can see what's going on.

Radial calipers / radial brakes.

Radial calipers / radial brakes.

Around the year 2003, motorbikes started to hit the showrooms with a new feature

- radial brakes. The magazines and testers will all tell you that radial brakes

make the bike stop quicker. Not true - they have nothing to do with stopping

power and everything to do with the design of the front forks of the bike. More

and more bikes are coming out with upside-down forks. ie. instead of the fat

canister part of the fork being at the bottom of the assembly, it's at the top.

This means that the fork pistons are now the part of the suspension with the

wheel attached to them. It also means that it's impossible to put a stiffening

fork brace down there now because the brace would need to move with the wheel,

and the length of the fork pistons precludes that.

The stiffness of the front end is now entirely dependent on the size of the

front axle. Bigger axle = stiffer front end. A side-effect of this design was

that traditionally-mounted brake calipers could cause a lot of vibration in the

steering because of flex between the wheel (with the brake disc bolted to it),

and the fork leg (with the caliper). The slight tolerance allowed by floating

brake rotors couldn't compensate for the amount of flexing in the forks. To

reduce the brake-induced fork vibration, the brake calipers were moved around

the rotors so that they fell into the radial line of the wheel. This is because

there is less lateral flex at that point, which means less or no vibration. It's

interesting to note that car brakes have been radially mounted for decades.

The image on the right here shows radially mounted brake calipers, and floating

brake rotors on a modern race-inspired motorbike.

Brake pad compounds.

Just a quick word on brake pad compounds. Most pads used to use

asbestos but we all know what that stuff is like. Today they use all manner of

combinations of materials.

The pads themselves are made up of a friction material bonded to the backing

plate. The brake caliper piston pushes against the backing plate and the

friction material is pushed against the brake rotor. The material combinations

typically fall into the following broad categories now.

- Organic

- These pads are well-suited for street driving because they wear well, are

easy on the ears, don't chew up the rotors and don't spew dust everywhere.

They're favoured for your average family saloon because they work well when

they're cold. Of course the drawback is that they don't work so well when they

get hot.

- Semi-metallic / sintered

- This is a good compromise between street and track. These seem to be the

pad of choice for sportier vehicles such as the Subaru Impreza WRX. They won't

work as well as organic pads when they are cold, so you need to be a bit wary

of the first couple of stops. Conversely they do work well when hot.

Occasionally the weak link in semi-metallic pads is the bonding material that

holds the friction pad to the backing plate. There have been occasions where

the friction material has come away completely. That's infrequent though.

- Metallic

- These pads are typically reserved for racing or the extremely rich. They

squeal and dust like crazy, are hard on rotors and don't work well when cold.

- Ceramic

- Ceramic pads still have metal fibers (about 15% vs. about 40% for

semi-metallic) but they are copper instead of steel and therefore cause less

wear and transfer heat better. They don't fade as easily as other pads, cool

faster, last longer, and are effectively silent, as the sound they genereate

is outside of the human range of hearing. Dogs will go crazy thought. The dust

created by ceramic pads is also very light in color so your wheels look

cleaner.

Brake squeal.

Squealing brakes are a sign of one of two things : the friction

material is all gone and you're jamming the backing plate against the brake

rotor, or the fit of the brake pad against the caliper piston isn't as snug as

it could be. Either way, the squealing is the result of an extremely

high-frequency vibration between the pad, the caliper piston and the brake

rotor. Some vehicles have problems with squealy brakes right from the factory.

In those cases, simply changing brake pad manufacturer can often cure the

problem as the different pads will have a slightly different harmonic frequency,

which is harder to attain. A classic example was one of the BMW R1100 touring

bikes. From the factory, they'd squeal like crazy, and BMW redesigned the brake

calipers and rotors a couple of times until they finally just switched to a

different brand of pads and the problem vanished.

Brake actuators.

Brakes are all well and good, but you need some method of

applying them in order for them to work. The method by which the force from your

hand or foot reaches the brake itself is all to do with the brake actuator

system.

Cable-operated

This is about as basic as you get. A cable is connected to a

lever at each end. You press on one lever with your foot or squeeze it with your

hand, and it pulls the lever at the other end. On the back of the brake-end

lever there's an elliptical cam which rotates inside a circular cup in the brake

shoe. As the long axis of the ellipse rotates, it forces the brake shoes to move

apart. In the case of a bicycle brake, the brake-end of the cable just pulls the

two calipers together.

Solid bar connection

One step up, and found on the rear brake of older motorbikes,

the solid bar connection. This allows the use of mechanical advantage (see

below) to amplify your force on the pedal or lever before it gets to the brakes

themselves. Typically these systems are used on drum brakes with the elliptical

actuator described above. The disadvantage of this system is that it needs hinge

and pivot points that match the position of the suspension components. If

they're not present, going over a bump could put the brakes on as the suspension

moves relative to the lever.

Single-circuit hydraulic

Another step up and we get to the type of brake system used on

most cars and motorbikes today. Gone are the cables and bars, replaced instead

with a system of plungers, reservoirs and hydraulic fluid. Single-circuit

hydraulic systems have three basic components - the master cylinder, the slave

cylinder and the reservoir. They're joined together with hydraulic hose and

filled with a non-compressible hydraulic fluid (see brake fluid below). When you

press your foot on the brake, or squeeze the brake lever, you compress a small

piston assembly in the master cylinder. Because the brake fluid does not

compress, that pressure is instantaneously transferred through the hydraulic

brake line to the slave cylinder where it acts on another piston assembly,

pushing it out. That slave assembly is either connected to a lever to activate

the brakes, or more commonly, is the brake caliper itself, with the slave

cylinder being the piston that acts directly on the brake pads. Because of the

arrangement of the slave cylinder, heat from the brakes can be transferred back

into the brake fluid.

Dual-circuit hydraulic

Dual-circuit hydraulic systems are available on high-end luxury

vehicles and newer motorbikes, in particular BMW bikes. These have two separate

circuits. One is the command circuit - that's the one you act on with your hand

or foot. The second is a separate circuit controlled by an onboard computer, and

that's the one which is actually connected to the brakes. As you apply the

brakes, you're sending a pressure signal via the command circuit to the brake

computer. It measures the amount of force you're applying, and using a servo /

pump system, applies the same force to the secondary circuit to activate the

brakes. If you do something stupid like trying to slam on the brakes at 100mph,

the computer will realise that this would result in a skid or spin, and will not

send the full pressure down the secondary circuit, instead deciding to use it's

speed and ABS sensors to determine the optimal brake pressure to maintain

control of the vehicle. The advantage of a dual-circuit system is that the

command circuit never gets heat transferred into it because it is totally

separated from the brakes themselves. The disadvantage of course is that you now

have two hydraulic circuits to maintain.

Brake-by-wire

The most advanced system of brakes to date are brake-by-wire.

These are a direct copy of Formula-1 racing brakes and are very similar to the

dual-circuit hydraulic system described above, but instead of the command

circuit being hydraulic, its replaced with electronics. The brake pedal or lever

is connected to a hypersensitive rheostat (measures electrical resistance). The

more you push it, the greater the electrical signal sent to the brake computer.

From there on, it performs just like the secondary circuit described above. The

advantage to this system is that the brake pedal or lever can be placed just

about anywhere you like as it no longer is encumbered by the plumbing that goes

with a hydraulic circuit. To combat driver complaints of "lack of feel" in the

brakes, most brake-by-wire systems have a reverse feedback loop built in. This

measures the pressure being applied to the brakes on the secondary circuit, and

actuates an electrical resistor in the pedal or lever assembly to provide

resistance. This is needed because there is no physical connection to any

part of the brake system at all.

Mechanical advantage - why you can stop a 2-ton car with one foot.

If you did any sort of physics classes when you were back in

school, you might remember something called mechanical advantage. In its most

basic form, mechanical advantage is the ratio of force-in to force-out in a

mechanical system. Mechanical Advantage = Effort Torque/Load Torque.

For example a 20kg weight 1 metre from a pivot can lift a 40kg weight 0.5m from

the pivot on the other side. The effort torque and load torque calculations are

to do with force in Newtons and distance from pivot point. Hence torque is

measured in Newton-metres, or Nm. Another popular notation is lbf.ft -

pound-force-feet, commonly referred to as foot-pounds. 1 Newton-metre is

equivalent to 0.737 foot-pounds.

The diagram below shows a simple lever system on a pivot. The load torque is

20Nm, and the effort torque is also 20Nm. Mechanical advantage = effort / load,

which in this case is 20 / 20, which is 1. ie. the system is balanced.

Now imagine increasing the weight on the effort side to 30kg

instead of 20kg, but leaving everything else the same. The load torque is still

20Nm, but the effort torque is now 30Nm. Mechanical advantage = effort / load,

which is 30 / 20, which is 1.5. Any mechanical advantage value larger than 1.0

means that the effort has the advantage. In this case, a 30kg weight which is

lighter than the 40kg load, is able to lift it off the ground.

If you now take your new-found / remembered knowledge about

physics and look at the simple lever brake system, you'll realise how it's

possible to generate enough force using your foot to stop a car or motorbike.

Look at this diagram of the lever-operated cam brake.

This system has 4 levers in it. The middle two have no

mechanical advantage as the levers are connected the same distance from the

pivot in each case. However, look at the pedal. The values I've put in are

arbitrary but they serve the purpose. On the pedal we have some amount of force

20cm from the pivot, but the other end of the lever is only 5cm from the pivot.

This gives us a mechanical advantage of 4 on the brake lever (20cm / 5cm).

At the other end, the lever attached to the cam is still a lever system - it's

just bent. The input lever is 10cm long but the cam is only 4cm across - or 2cm

to the tip from the pivot. So at the brake cam we have a mechanical advantage of

5. (10cm / 2cm). So across this entire system, we have a total mechanical

advantage of 20 - 4 from the brake pedal and 5 from the lever and cam. Apply

force to this little system and be amazed. The units of force used are

irrelevant - they're multiplied just the same. To use easier-to-comprehend

values, let's imagine that when you're braking, your foot is pushing on the

brake pedal with about 60pounds of force - 27Kg. Through the brake pedal, that

is amplified 4 times to 240pounds, and through the lever and cam its amplified a

further 5 times from 240pounds to 1200pounds. You pushed the pedal with 60pounds

of force, but the cam inside the drum brake is being forced out against the

brake drum with 1200pounds of force - about 544Kg. Sweet.

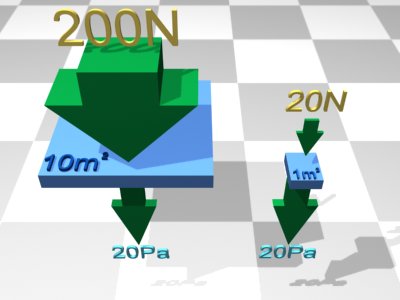

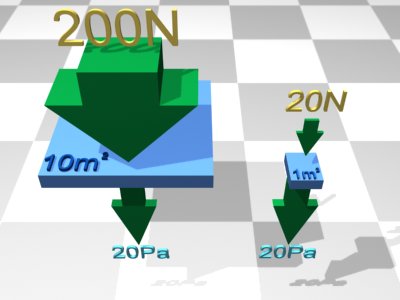

Mechanical advantage as applied to hydraulics.

Most braking systems now use hydraulics. This is a slight change

in the equation but the concept of mechanical advantage still exists, this time

by the use of pressure equations. Pressure = force / area. If you apply 20

Newtons of pressure to 1m², it's the same as applying 200 Newtons to 10m². Why?

Because 20 Newtons of force divided by 1m² of area generates 20 Pascals of

pressure. Similarly, 200N / 10m² is also 20Pa.

If you now think of that in terms of a hydraulic braking system,

it becomes clear how mechanical advantage works for you. Brake fluid is

incompressible - it has to be. This is good because it makes calculation for

hydraulic brake systems quite easy - you can eliminate the internal pressure

from the equation.

Split the system into two parts - input and output - the brake pedal and the

brake caliper piston.

For each part, Pressure = Force / Area. The Pressure is the same at all points

in the system, so some basic algebra gives a simple formula:

Using our previous example, we apply 60pounds (27Kg) of input

force to the brake pedal. This is attached to a master piston which (for

example) is 1.25cm across - ie. it has a surface area of 0.000491m² (remember

your maths? area = PI x r²). At the other end of the system is the caliper

piston, which for example is 2cm across - ie. it has a surface area of

0.001257m². Using our sparkly new formula, the output force from the caliper

piston is

60 x (0.001257m² / 0.000491m²) Get your calculator out and that comes out to

154pounds (69.8Kg) - more than double the force at the brake pedal. The ratio of

output area to input area is sometimes referred to as the area differential.

So that, my friend, is why you can stop a speeding vehicle with a single foot.

Power Brakes and master cylinders.

Power brakes (also known as power assisted brakes) are designed

to use the power of the engine and/or battery to enhance your braking power.

Whilst you can generate a fair amount of force using your foot, using systems

from elsewhere in the car to help you apply even more force means that you get

more powerful brakes as a result.

The four most common types of power brakes are: vacuum suspended; air suspended;

hydraulic booster, and electrohydraulic booster. Most cars use vacuum suspended

units (vacuum boosters). In this type of system, when you press the brake pedal,

the push rod to the master cylinder opens a vacuum control valve. This allows

vacuum pressure (normally from the intake manifold) to "suck" on a diaphragm

inside the vacuum assist unit. This extra vacuum suction helps you to produce

more force at the pedal end of the brake system.

You'll notice in the image below (which I scurrilously had to modify from

someone else's site - if that's you, I apologise), that the master cylinder has

two brake circuits and two master pistons. These circuits are separate and are

typically connected to the front-left and rear-right wheel on the first circuit,

and the front-right and rear-left wheels on the secondary circuit. This means

that if one circuit fails, the second one will still work and it will still

apply braking force to the front and rear of the car.

Hydraulic booster systems usually utilise pressure from the

power steering system to augment pressure on the master brake cylinder.

Electrohydraulic booster systems use an electric motor to pressurize the

hydraulic system downwind of the brake pedal which has the effect of amplifying

the internal pressure in the whole system.The advantage to this system is that

as long as you have battery power, you have power brakes even if the engine

fails. With vacuum-assist brakes, no engine means no assistance.

If you're curious about how power brakes work, go out to your car and with the

engine off, step on the brakes. They'll have a slightly solid, almost wooden

feel to them. Turn the engine on and do it again and you'll notice a lot less

back-pressure on the pedal. This is the power assist which is making it easier

for you to depress the pedal.

One last thing about brake master cylinders : they cost an absolute bomb to

replace. If you find yours is leaking, patching it up is not an option. Brand

new master cylinders can go for around $1500 without labour costs.

Remanufactured ones come in slightly cheaper at around $900. Bear that in mind

when your 20 year old beater develops a leak - it's probably cheaper to buy

another used car than to replace the master cylinder.

Anti lock Braking Systems - ABS

Stop without skidding, and maintain control of the vehicle.

That's the premise of ABS. It was first introduced in the 1980's and has been

undergoing constant refinement ever since. The system is typically comprised of

4 ABS rings, 4 sensors, an ABS computer and a pressure-management system in the

brake line. The ABS rings are attached either to the wheels, or more often, to

the brake discs. They look like a notched ring - see the image below.

The sensors are magnetic field sensors which are held very close

to the ABS rings and can detect the slight change in magnetic field as the teeth

on the ring pass them. The pulsing field tells the ABS computer that the wheels

are spinning, and how fast they're spinning.

When you brake, the wheel rotation starts to slow down. The ABS computer

"listens" to the input from the sensors and can detect if one wheel is slowing

down much quicker than the others - the precursor to the wheel locking up. This

all happens in milliseconds, by the way. When the computer detects this

condition, the pressure regulator interrupts the pressure in the brake lines by

momentarily reducing the pressure so that the brakes give the wheels a chance to

keep spinning rather than locking up. The computer then instructs the regulator

to re-apply full pressure and again measures the wheel rotation. This

on/off/measure cycle happens around 15 to 30 times a second. If the ABS kicks

in, you'll feel it through the brake pedal as a vibration because the pulsing in

the brake circuit affects all the components.

Newer generation ABS systems

As technology marches on, so does the control / feedback system

used in ABS. It used to be the case that any single wheel approaching lockup

would cause the ABS system to pulse the brake pressure for all the wheels. With

the latest vehicles, the ABS computer is connected to 4 pressure regulators

instead of just the one. This means it can selectively apply pulsed braking only

to the wheel(s) that need it. So if three of the tyres are gripping well, but

the front-left is beginning to skid, the ABS can unlock the front-left brake and

pulse it to try to regain grip. It's all very James Bond.

ABS and skid control

The biggest misconception about ABS is that it will make you

stop faster. This is absolutely not true. ABS has nothing to do with stopping

power and everything to do with maintaining control of your vehicle, be it a

car, truck or motorbike. The problem with skidding whilst braking is that it

removes you from ultimate control of where the vehicle is going. On a motorbike,

skidding invariably causes highsides, flips and general thoughts of "huh?" to

the rider as he's flying through the air towards certain pain. In a car or

truck, skidding stops the vehicle from going where you want it to, and instead

makes it straight-line based on the camber of the road, the speed of the vehicle

and how much damage it can do to your insurance policy.

Skidding is caused because the wheels lock up. Once they stop rotating, the

tyres can no longer grip the road surface and begin to skate across it. When

that happens, it really makes no difference where the steering is pointing

because without grip, steering is useless.

With ABS, the idea is that the wheels don't ever lock up, so you still have

control over the steering. The wheels keep going around, so the tyres keep

gripping, so the steering is effective. That's where ABS gets its name -

Anti-Lock Brakes.

The bone of contention with ABS

So many people think ABS gives them a license to drive faster,

because they mistakenly believe that ABS will get them out of any situation.

It's yet another technical placebo that has been put into vehicles which is

making the standard of driving worse. The more gadgets and "driver aids" that

get put into a car, the worse the drivers become because they live in a

pink-spectacled world where they believe that the car will get them out of any

problem they cause. It bothers me so much I have a "rant" page dedicated to it

here :

Nanny Cars.

Personally I don't like ABS. I don't like the idea of a computer interrupting

the connection between my right foot and the brakes. It also doesn't work worth

a damn on gravel or in the snow. With regular brakes, in the snow, you can jam

them on and at least stand a chance of the tyres digging in and finding the road

surface. With ABS the system will just take the brakes off and you'll skate

merrily along on the snow with no chance of slowing down.

The hidden gremlin of ABS - what they don't advertise.

If you look at the statistics for crashes, a large percentage of

them are "fender benders" - low-speed impacts that only do a little damage and

so slow that the vehicle occupants are in no danger. Less than 15mph normally.

I'll give you one guess what the typical "minimum activation speed" is for ABS.

That's right. Your average ABS system is useless much below 15mph. Seriously.

Try it yourself. Find an empty road on a slight downhill grade - even better if

its on a dewy morning. Run your ABS-equipped car up to about 15mph and jam on

the brakes as hard as you can. The car will skid to a stop and the ABS system

will remain totally silent.

Aftermarket ABS systems

To the best of my knowledge, there's no such thing. A few years

back a couple of companies tried to market what they called ABS systems that

could be retrofitted to any vehicle. The product was a cylinder with a

pressure-relief valve in it. The idea was that you inserted this system into the

brake circuit somewhere. When you stomped on the brakes - symptomatic of locking

up the wheels - the pressure relief valve opened and bled off some brake fluid

into the cylinder, thus lowering the braking pressure being sent to the wheels.

The idea was to take the "spike" off the initial push of the brake pedal so it

wasn't ABS at all. The whole idea of putting something like this into a brake

circuit makes me shudder - I wouldn't want to be the person trying to get their

insurance and medical claims through after an accident when the investigators

found one of these contraptions in their brake line!

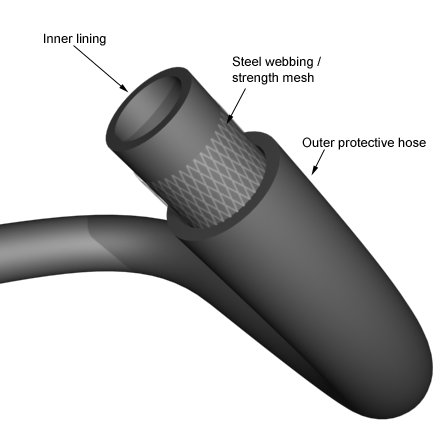

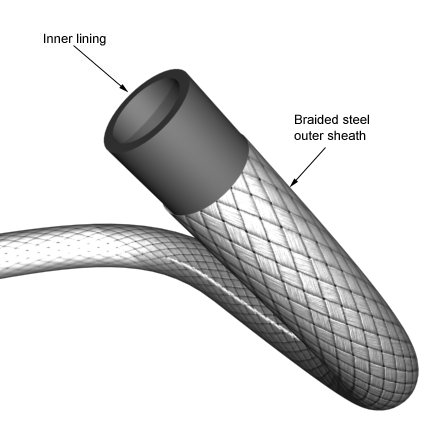

Brake hoses - not just rubber.

Obviously with all the pressure in your brake system, the last

thing you need is for the brake lines themselves to deform and flex. If they do,

you lose brake pressure, and thus lose braking. Steel brake lines are no

problem, but for the flexible areas of the brake lines, you need hoses. Brake

hoses come in two basic flavours.

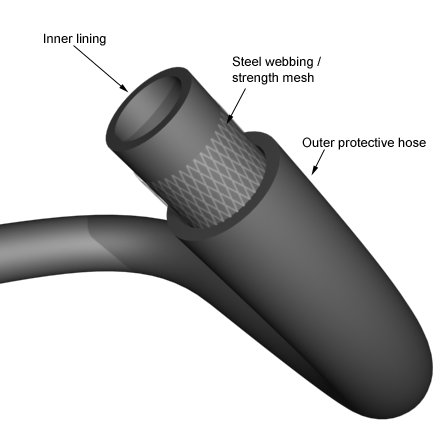

Rubber hoses.

Ah the humble rubber hose. Only on your brake lines, not so

humble. I don't recommend this but if you were to get under your car and cut one

of your hoses in half, you'd notice a couple of things. First, it's amazing how

quick all the brake fluid that spills out will stain your clothes and literally

eat the paint off your car right in front of you. But second, and more

importantly, the hose itself is actually made of three parts. The inner liner is

a corrosion and brake-fluid resistant compound designed (normally PTFE / Teflon®

based) purely to keep the brake fluid in. Around the outside of that, there's a

steel webbed mesh. This is what gives the brake hose its strength and stops it

from bulging and deforming. And around the outside of that there's a slightly

thicker rubber coating, which is there to weatherproof the steel mesh. The three

layers together give strength, flexibility and durability.

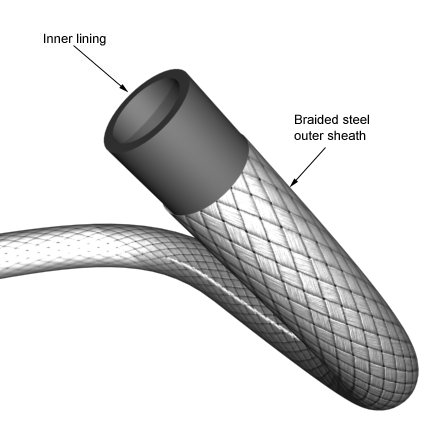

Steel-braided hoses.

Steel-braided hoses are a slightly different design. They only

really have two components - the inner hose which carries the brake fluid and is

lined with a PTFE compound, and the outer steel braid which contains and flexing

or bulging. Steel-braided lines resist bulging a lot better which is why a lot

of aftermarket tuners opt to put them on their vehicles. One downside is that

the steel braiding itself is totally merciless and if it finds something to rub

against in the vehicle, it will rub right through it, even if it's an alloy. For

that reason, a lot of braided brake hose manufacturers put a third layer - a

thin transparent rubber sheath around the outside simply to keep everything in

check and prevent scuffing and rubbing.

I upgraded the lines on my Audi when I still owned it and put Goodridge steel

braided hoses on. For a 15 year old car it did make a difference to the feel of

the brake pedal. It didn't bring it up to modern standards, but it was better

than the flexible, bendy rubber hoses that were on it from the factory.

Brake fluids.

As

mentioned elsewhere on the page, brake fluid does not compress. It's a good job

too - if you put your foot on the brake pedal and it went all the way to the

floor, you'd be worried. But that's exactly what can happen if you disregard the

"health" of your brake fluid.

As

mentioned elsewhere on the page, brake fluid does not compress. It's a good job

too - if you put your foot on the brake pedal and it went all the way to the

floor, you'd be worried. But that's exactly what can happen if you disregard the

"health" of your brake fluid.

Brake fluid is hygroscopic - that means it attracts and soaks up water. This is

why it comes in sealed containers when you buy it, and why when the crazy guy

four doors down offers you some of the 15 gallons of brake fluid he's had in his

garage since the war, you should turn him down. The problem with it being

hygroscopic is that if it does start to take on water, Bad Things can happen.

Pull up a chair and allow me to explain.

Your typical DOT 4 brake fluid (see later for DOT ratings) boils at about 446°F

(230°C). Water boils at 212°F (100°C). Imagine your brakes are getting hot

because of a long downhill stretch. Whilst the brake fluid is quite OK, the

temperature of the brake components might get up over the boiling point of

water. If that happens, the water boils out of the brake fluid and forms steam -

a compressible gas. Next time you put your foot on the brake, rather than

braking, all the pressure in the brake system is taken up with compressing the

steam. Your brakes go out, you don't stop.

Getting a little more complex, the boiling point of a liquid goes up with its

pressure (Physics 101). So when you step on the brake, the boiling point of the

brake fluid might actually go up to 500°F (260°C) and the boiling point of the

water content might raise up to 250°F (121°C). This is great, you might think,

because now the boiling point is higher than the temperature of the brake fluid.

At least it is until you take your foot off the brake again. Now the pressure in

the system returns to normal, the boiling points revert to normal and instantly

the water boils off into steam again. The symptoms are slightly different now.

Under this scenario, the brakes work the first one or two times, but on the

third or fourth press, they stop working because now the temperature and

pressures have conspired to boil the water.

The worst possible scenario is brake-fade (see right at the top) combined with

air in the system. If this has happened to you, then you're likely reading this

page from beyond the grave, because in most accidents where weak brakes become

no brakes, there aren't any survivors.

D.O.T ratings

All brake fluids are DOT rated. Your owners handbook for your

car or motorbike probably tells you to use DOT3 or DOT4 from a sealed container.

The DOT ratings are a set of minimum standards the fluid must adhere to

in order to get the rating, and thus work in your braking system. The following

table shows the various properties of DOT ratings. Remember that the values here

are the minimum values. Most manufacturers make sure their product far exceeds

minimum ratings.

| Boiling Point |

DOT 3 |

DOT 4 |

DOT 5 (silicone-based) |

DOT 5.1 (non-silicone based) |

| Dry |

401°F |

446°F |

500°F |

500°F |

| Wet |

284°F |

311°F |

365°F |

365°F |

The "dry" and "wet" boiling points in the table above are for

brake fluid which is fresh from the bottle (dry) and which has a 10% water

content (wet). A DOT study in 2000 discovered that on average, the brake fluid

in a vehicle absorbs about 2% water every 12 months.

The two types of brake fluids shown in the table are DOT3/DOT4/DOT5.1 which are

glycol (Polyalkylene Glycol Ether) based, and DOT5 which is silicone based. DOT3

and DOT4 fluids are interchangeable - the only real difference is their boiling

point. Theoretically you could interchange DOT4 and DOT5.1 fluids too but I

wouldn't recommend it. DOT3/4/5.1 and DOT5 fluids cannot be mixed or

interchanged under any circumstances. They mix like oil and water (ie. they

don't) and the silicon based fluids can destroy the seals in brake systems which

rely on the moisturiser additives that are present in DOT3/4/5.1 fluids.

Other things you ought to know about silicone based fluids:

- they are resistant to absorbing water, which is why their wet boiling points

are so high. Problem is that any water content eventually pools in the low spots

of the brake system and causes rust.

- they don't strip paint.

- they are not compatible with most ABS system because they doesn't lubricate

the ABS pump like a glycol based fluid.

- putting this fluid in systems which have had DOT3/4 fluid in will cause the

seals in the caliper and master cylinders to malfunction. Which means they need

replacing. Which is expensive.

Oh, and don't ask me why DOT5.1 is glycol and DOT5 is silicon based. It doesn't

make and sense to me either.

Brake warning lights

Most cars

nowadays have a brake warning light on the dash. Its purpose is to alert you

that something is wrong in the braking system somewhere. If it comes on, check

your owner's manual to find out its meaning. Unlike the single-purpose ABS

warning light, the brake warning light doesn't have a standard meaning; it could

be used for multiple purposes. For example, the same light may be used to show

that the hand brake (parking brake for the Americans amongst you) is on. If

that's the case and you're driving, you ought to have noticed the smell of

burning brake dust by now. The light can also indicate that the fluid in the

master cylinder is low. Each manufacturer has a different use and standard for

this light. Which is nice. Because it would be such a drag if the same indicator

meant the same thing in every vehicle.

Most cars

nowadays have a brake warning light on the dash. Its purpose is to alert you

that something is wrong in the braking system somewhere. If it comes on, check

your owner's manual to find out its meaning. Unlike the single-purpose ABS

warning light, the brake warning light doesn't have a standard meaning; it could

be used for multiple purposes. For example, the same light may be used to show

that the hand brake (parking brake for the Americans amongst you) is on. If

that's the case and you're driving, you ought to have noticed the smell of

burning brake dust by now. The light can also indicate that the fluid in the

master cylinder is low. Each manufacturer has a different use and standard for

this light. Which is nice. Because it would be such a drag if the same indicator

meant the same thing in every vehicle.

If you've got

an ABS-equipped car, you also have a second light - the ABS light. If it comes

on, get it seen to as soon as possible. It means the ABS computer has diagnosed

that something is amiss in the system. It could be something as simple as dirt

in one of the sensors, or something as costly as an entire ABS unit replacement.

Either way, if that light is on, then you, my friend, have got 1970's brakes.

It's important to note that this light normally comes on when you start the car

and then switches off a few seconds later. If it stays on, blinks, throbs,

flashes or in any other way draws your attention to itself, take note. It's not

doing it just to please itself.

If you've got

an ABS-equipped car, you also have a second light - the ABS light. If it comes

on, get it seen to as soon as possible. It means the ABS computer has diagnosed

that something is amiss in the system. It could be something as simple as dirt

in one of the sensors, or something as costly as an entire ABS unit replacement.

Either way, if that light is on, then you, my friend, have got 1970's brakes.

It's important to note that this light normally comes on when you start the car

and then switches off a few seconds later. If it stays on, blinks, throbs,

flashes or in any other way draws your attention to itself, take note. It's not

doing it just to please itself.

If you ride a

motorbike or drive a race car, you're probably familiar with the term brake

fade which is used to describe what happens to brakes when they get too hot.

A good example is coming down a mountain pass using your brakes rather than your

engine to slow you down. By the First Law of Thermodynamics, as you start to

come down the pass, the brakes on your vehicle heat up, slowing you down. But if

you keep using the brakes, the drums or discs and brake pads will stay hot and

get no chance to cool off. The next time you try to brake, because the brake

components are already so hot, they cannot absorb much more heat. Once they get

to this stage, you have to look at the brake pads themselves. In every brake pad

there is the friction material which is held together with some sort of resin.

Once this lot starts to get too hot, the resin holding the pad material together

starts to vapourise, forming a gas. That gas has to have somewhere to go,

because it can't stay between the pad and the rotor, so if forms a thin layer

between the two trying to escape. The result is very similar to hydroplaning

while going too fast in the rain; the pads lose contact with the rotor, thus

reducing the amount of friction. Voila. Brake fade.

If you ride a

motorbike or drive a race car, you're probably familiar with the term brake

fade which is used to describe what happens to brakes when they get too hot.

A good example is coming down a mountain pass using your brakes rather than your

engine to slow you down. By the First Law of Thermodynamics, as you start to

come down the pass, the brakes on your vehicle heat up, slowing you down. But if

you keep using the brakes, the drums or discs and brake pads will stay hot and

get no chance to cool off. The next time you try to brake, because the brake

components are already so hot, they cannot absorb much more heat. Once they get

to this stage, you have to look at the brake pads themselves. In every brake pad

there is the friction material which is held together with some sort of resin.

Once this lot starts to get too hot, the resin holding the pad material together

starts to vapourise, forming a gas. That gas has to have somewhere to go,

because it can't stay between the pad and the rotor, so if forms a thin layer

between the two trying to escape. The result is very similar to hydroplaning

while going too fast in the rain; the pads lose contact with the rotor, thus

reducing the amount of friction. Voila. Brake fade.

Radial calipers / radial brakes.

Radial calipers / radial brakes.

As

mentioned elsewhere on the page, brake fluid does not compress. It's a good job

too - if you put your foot on the brake pedal and it went all the way to the

floor, you'd be worried. But that's exactly what can happen if you disregard the

"health" of your brake fluid.

As

mentioned elsewhere on the page, brake fluid does not compress. It's a good job

too - if you put your foot on the brake pedal and it went all the way to the

floor, you'd be worried. But that's exactly what can happen if you disregard the

"health" of your brake fluid. Most cars

nowadays have a brake warning light on the dash. Its purpose is to alert you

that something is wrong in the braking system somewhere. If it comes on, check

your owner's manual to find out its meaning. Unlike the single-purpose ABS

warning light, the brake warning light doesn't have a standard meaning; it could

be used for multiple purposes. For example, the same light may be used to show

that the hand brake (parking brake for the Americans amongst you) is on. If

that's the case and you're driving, you ought to have noticed the smell of

burning brake dust by now. The light can also indicate that the fluid in the

master cylinder is low. Each manufacturer has a different use and standard for

this light. Which is nice. Because it would be such a drag if the same indicator

meant the same thing in every vehicle.

Most cars

nowadays have a brake warning light on the dash. Its purpose is to alert you

that something is wrong in the braking system somewhere. If it comes on, check

your owner's manual to find out its meaning. Unlike the single-purpose ABS

warning light, the brake warning light doesn't have a standard meaning; it could

be used for multiple purposes. For example, the same light may be used to show

that the hand brake (parking brake for the Americans amongst you) is on. If

that's the case and you're driving, you ought to have noticed the smell of

burning brake dust by now. The light can also indicate that the fluid in the

master cylinder is low. Each manufacturer has a different use and standard for

this light. Which is nice. Because it would be such a drag if the same indicator

meant the same thing in every vehicle.  If you've got

an ABS-equipped car, you also have a second light - the ABS light. If it comes

on, get it seen to as soon as possible. It means the ABS computer has diagnosed

that something is amiss in the system. It could be something as simple as dirt

in one of the sensors, or something as costly as an entire ABS unit replacement.

Either way, if that light is on, then you, my friend, have got 1970's brakes.

It's important to note that this light normally comes on when you start the car

and then switches off a few seconds later. If it stays on, blinks, throbs,

flashes or in any other way draws your attention to itself, take note. It's not

doing it just to please itself.

If you've got

an ABS-equipped car, you also have a second light - the ABS light. If it comes

on, get it seen to as soon as possible. It means the ABS computer has diagnosed

that something is amiss in the system. It could be something as simple as dirt

in one of the sensors, or something as costly as an entire ABS unit replacement.

Either way, if that light is on, then you, my friend, have got 1970's brakes.

It's important to note that this light normally comes on when you start the car

and then switches off a few seconds later. If it stays on, blinks, throbs,

flashes or in any other way draws your attention to itself, take note. It's not

doing it just to please itself.